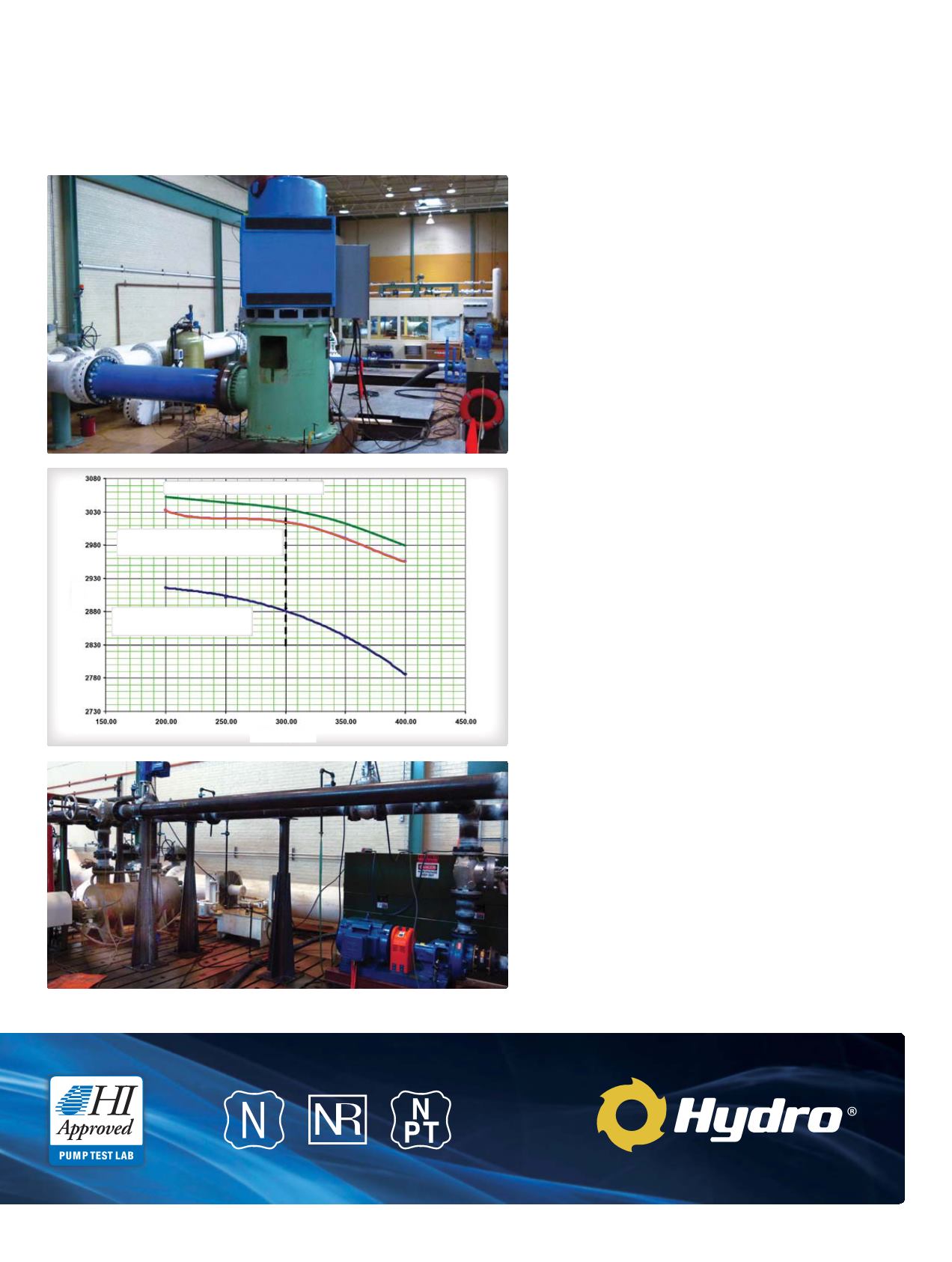

Endurance Testing for Service Water Pump

A 48-hour endurance test was performed for a

nuclear power plant when they contacted HydroAire

about conducting a research study. The power plant

engineers wanted to collect data to assess how

long the 1750 HP motor driving their essential

service water pump could continue to operate with

a deteriorating lower bearing. To learn the complete

details of this research study, contact Faisal Salman

a

t

or call

312-399-9913

.

Performance Testing for Safety Injection Pump

Within a critical 2-week timeframe, HydroAire

helped a nuclear power plant avoid de-rating by

reverse engineering and rebuilding a Goulds

8-stagesafety injection pump rotor. The rotor, rebuilt

with engineered upgrades, was performance tested.

Performance was proven at 1288lbs. pressure –

8lbs. better than the original rotor and 88lbs. above

the minimum allowance. Read the full case study

at

Air Void Testing for Safety-Related Feed Pump

Hydro's engineers performed 40 air void tests in

10 days for a nuclear power company that had to

prove their Pacific 4” BFIDS auxiliary feed pump

would perform its safety-related service if an air

void greater than 2% passed through the pump.

Hydro’s Test Lab provided a live video feed of

real-time performance data for the NRC to monitor.

Read the full case study at

Proven Experience

Makes All The Difference

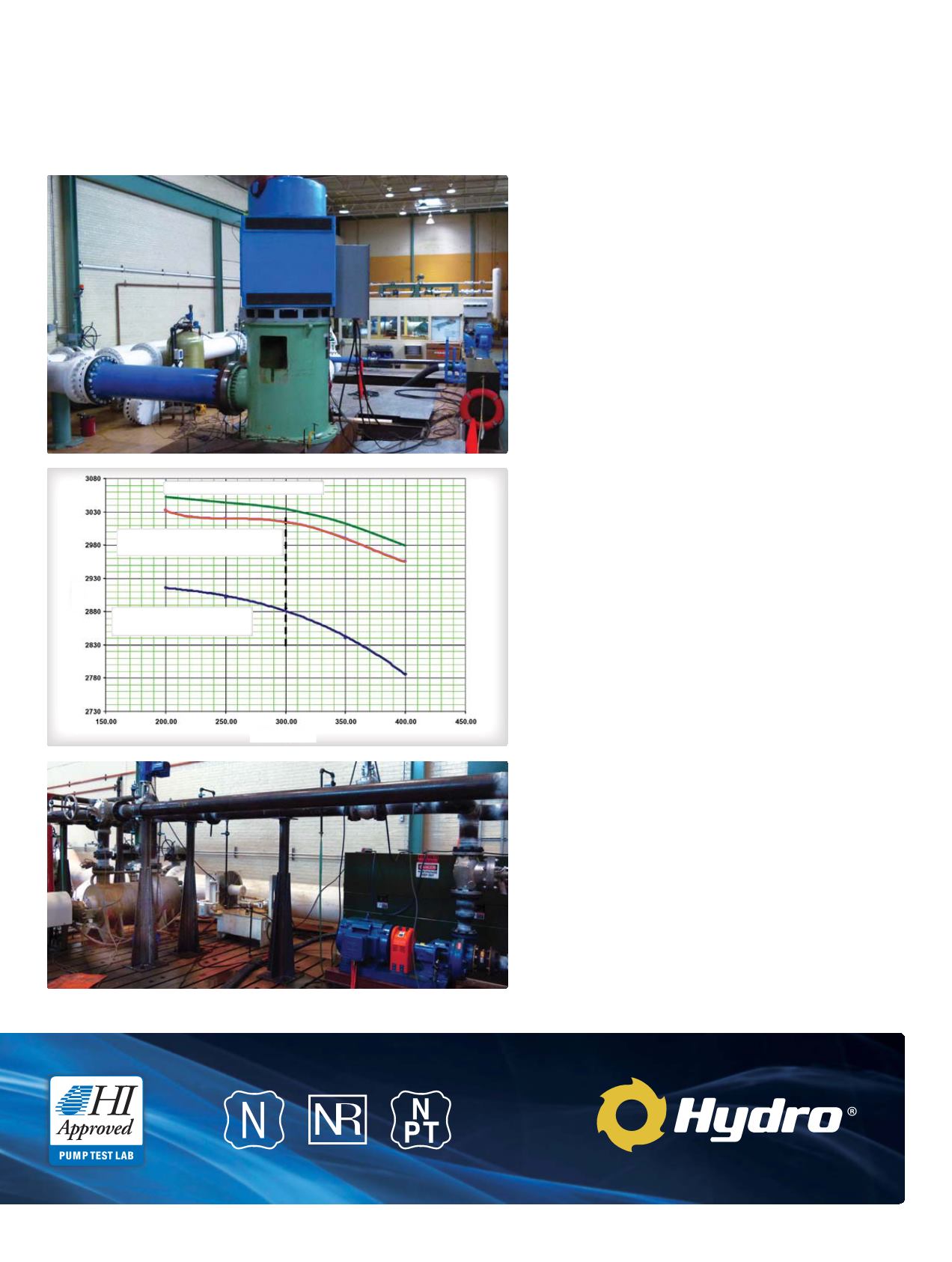

Actual Performance of Underfiled Impeller

Projected Performance of Impeller with

underfiling using Hydro's in-house program

Impeller without Underfiling

(spare rotor)

Characteristic curves

H (ft)

Flow (GPM)