As U.S. utilities seek plant life extension

to 60 years and beyond, management

of aging components is a critical factor

to operational excellence. With long

lead-times and lack of availability,

the costs associated with replacing

obsolete equipment start to add up.

Plant operators are performing more

required maintenance tasks than

ever with shrinking resources. At

times like these, you need innovative

solutions that bring value to your aging

component challenges.

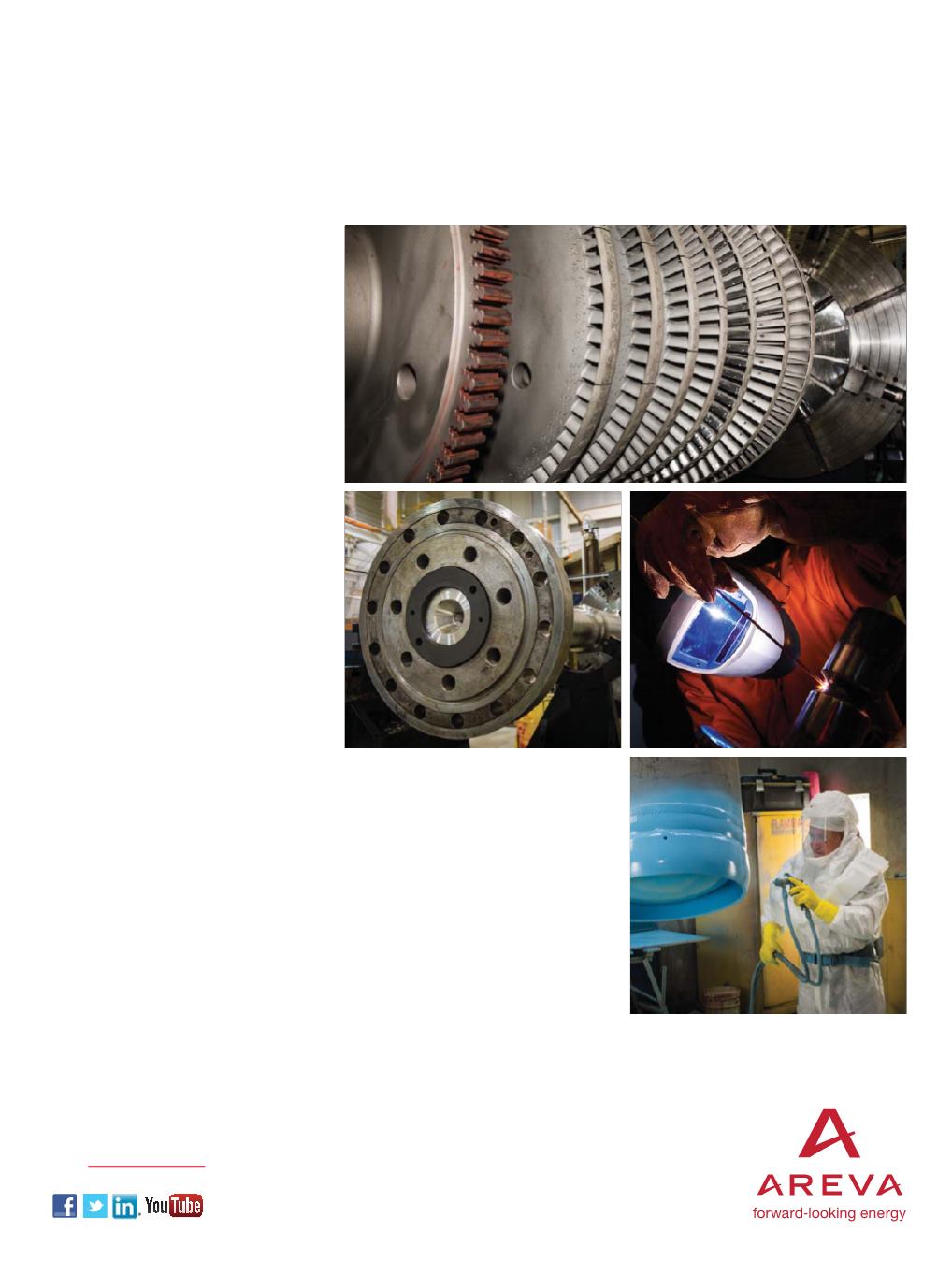

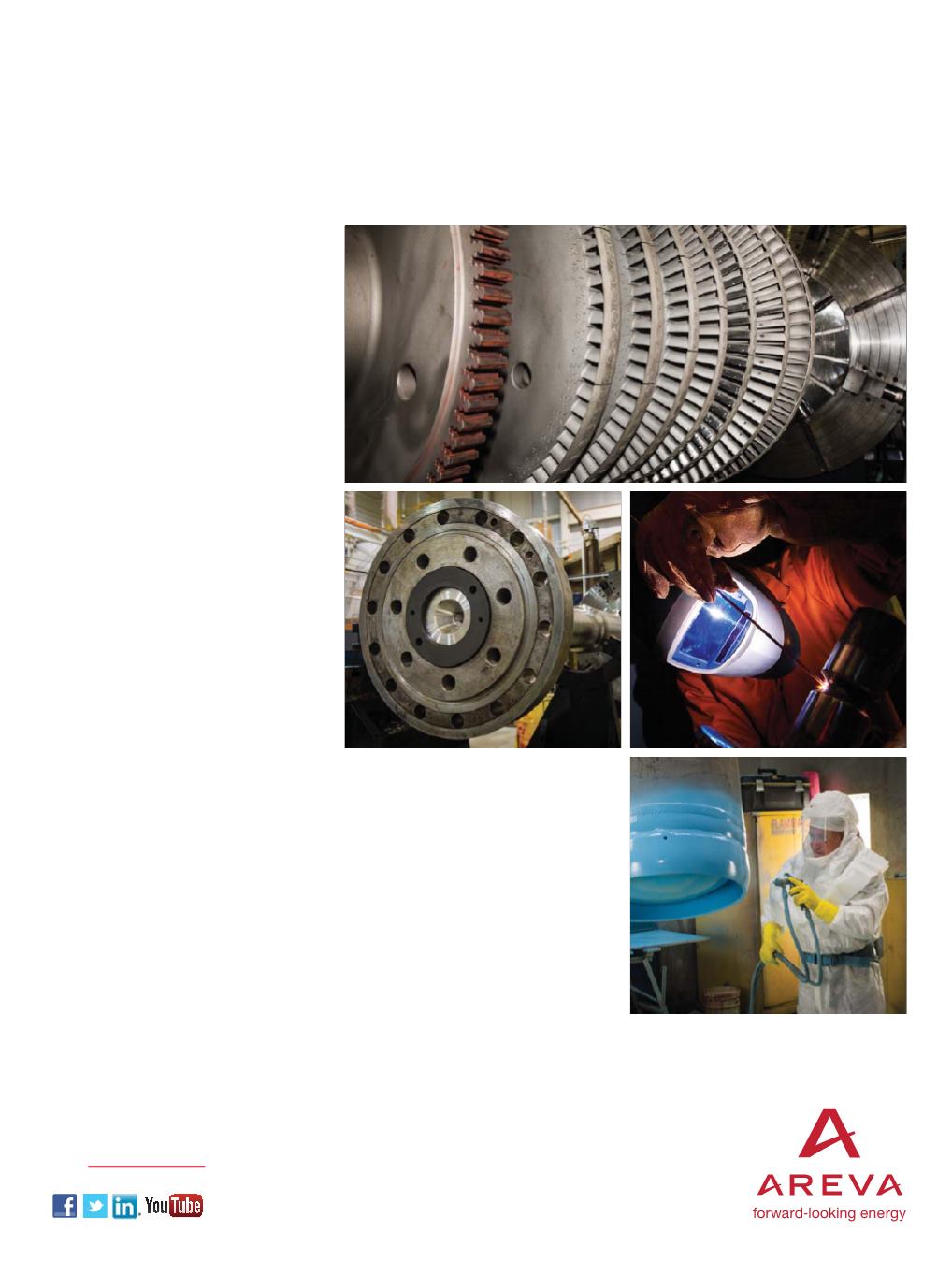

AREVA’s dedicated service

professionals are here to help

with extensive in-house repair and

refurbishment capabilities at our

Contaminated Refurbishment Center

(CRC) — located within AREVA’s

world-class Pump & Motor Service

Center. With a 20,000 ft

2

radiologically

controlled area, our hot and clean

shops contain a wide array of

equipment to meet machining, welding,

and repair challenges for both primary

and secondary side components.

AREVA’s Specialty

Maintenance Solutions

Contaminated Machining, Welding, and Fabrication

to Address All Your Maintenance Challenges

Specialty Maintenance Portfolio

• Heat exchanger repair

– Tube sleeving

– Tube plugging

– Flange face machining

• Reactor feed pump turbine services

– Inspection

– Blade replacement

– Balancing

• Primary pump seal forensics

• Secondary side pump repair

• ECCS pump repair

• Contaminated valve repair

• RCP seal housing weld repair

• Specialty equipment refurbishment

– Yoke arm repair

– RV guide stud repair

– Lifting beams and fixtures

Advertorial

To learn more about AREVA’s

specialty maintenance solutions,

SPECIAL ADVERTISING SECTION