Benefits of

Research

By Neil Wilmshurst, Electric Power

Research Institute.

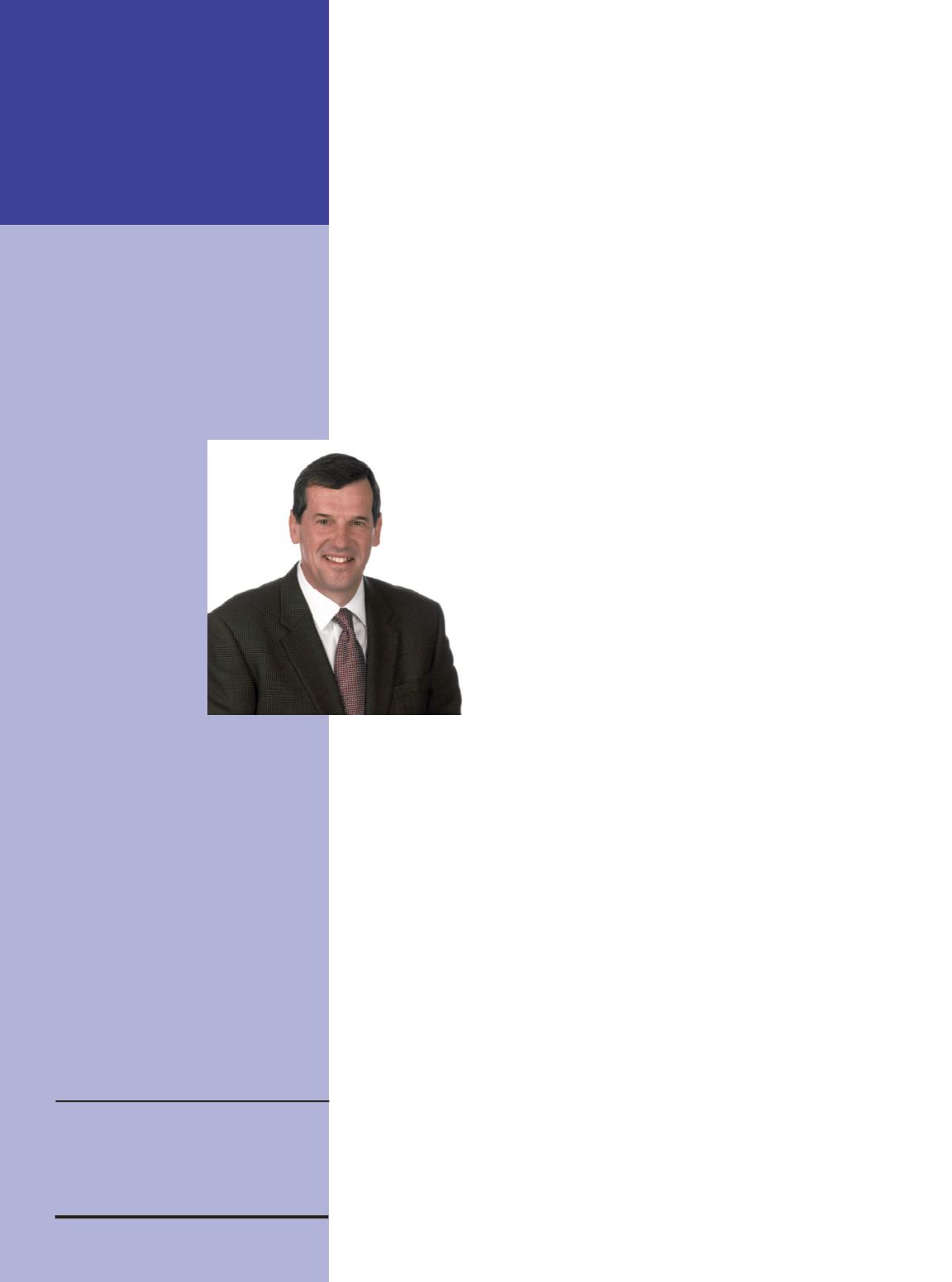

Neil Wilmshurst

Neil Wilmshurst is Vice President of

Nuclear for the Electric Power Research

Institute (EPRI). He has overall

management and technical responsibility

for the more than $160 million in annual

research activities conducted by EPRI

with its global nuclear membership.

Wilmshurst

joined EPRI’s

Plant Support

Engineering

Program in 2003,

and became

Director of the

Plant Technology

department in 2008.

Before joining

EPRI, Wilmshurst

worked in a variety

of nuclear utility

engineering and

maintenance roles

with AmerGen and

British Energy. Prior to joining the civil

nuclear program, Wilmshurst served for

13 years in the Royal Navy as a Nuclear

Submarine Engineer Officer.

Wilmshurst received a bachelor’s degree

in electrical, mechanical and control

engineering from the Royal Naval

Engineering College, Manadon, UK,

a Post Graduate Diploma in nuclear

reactor technology from the Royal Naval

College, Greenwich, UK and a master’s

degree in defense administration from

Cranfield Institute of Technology,

Shrivenham, UK. He was also certified

as a Naval Nuclear Plant Operator.

An interview by Newal Agnihotri,

Editor of Nuclear Plant Journal, at

the American Nuclear Society Utility

Working Conference in Amelia Island,

Florida on August 11 ,2014.

1.

How can a tablet be used in nuclear

power plant maintenance?

Over the years, our Nuclear

Maintenance Application Center has been

very successful in producing paper-based

maintenance guides on dozens of different

maintenance tasks, overhauling motors,

replacing chemical seals, things as simple

as torqueing flanges to make sure they’re

leak tight. We’ve got a huge library and

a huge amount of expertise that is paper

based. So, when you sit back and look at

the way the new generation is working,

we came to the realization that we needed

to transition our delivery to things like

tablets.

Because the nuclear industry is

necessarily conservative, it takes time to

move ideas like this along. We’ve had

plants in the US and

around the world

that have started

installing wireless

networks. I think

Comanche

Peak

was one of the

first, and there are

other plants around

the country which

also have wireless

networks inside the

plant. The full value

is realized when you

can link that wireless

network to a tablet-

based maintenance program, and have

the capability to capture the procedures,

the check sheets, the walk-down logs on

a tablet, and then transfer that information

in real time back to the plant’s computer

systems.

We’re even looking at doing things

like using pattern recognition software,

so that just by looking at a valve and the

position of the handle, we can tell whether

the valve is open or not. You have a

picture in the database that shows where

the handle is when it’s open and where the

handle is when it’s shut. You then take a

photograph of an area and the system gives

you the valve alignments. It’s not ready to

be deployed yet, but that’s an example of

where things could go.

We have a very close relationship

with INPO, which identified some time

ago that one of the components they were

really concerned about was air-operated

valve (AOV) maintenance. So, we picked

that as the first one to look at for what

could we do using a tablet or computer-

based app. We actually went to a company

that produces computer games to help

us develop this app. We took the CAD

information for the AOV, and we built

a ‘game’ using an AOV, how you take it

apart, how you put it together, how you

test it, what tools you use. The ultimate

goal is to help people understand the AOV

before they go to the field, understand

what the job is, and see how things work

and how things fit together. It’s been very

well received, and we’re doing a few more

of those.

EPRI’s role isn’t necessarily to be

the source of these tablet applications for

every component in the nuclear industry.

Our role is to demonstrate to the world

what is possible and what can be done.

Then if someone wants to commercialize

that and take it, our role is to basically

enable whoever wants to take it and

help the industry. We’re just looking to

demonstrate what’s possible.

2.

How is EPRI’s nuclear research

funded?

Our funding comes, traditionally,

from utility members. We started 40+

years ago, and EPRI was a US-focused

organization, but we are increasingly

becoming a global organization. Our

independence, objectivity, and the quality

of our people and our research encourage

companies to join. I wouldn’t say that

we really sell anything. We live by our

independence and our reputation. And

people come to us wanting to join because

of that.

3.

What efforts are underway with

respect to accident-tolerant fuel designs?

People have talked about opportunities

to remove zirconium from nuclear fuel

assemblies for a long time. Some of the

hydrogen at Fukushima was generated via

zirconium oxidation; additional hydrogen

likely came from corium-concrete

interactions. Without zirconium, however,

the operators may have had several hours

longer to actually get water in the cores.

So, while I don’t think the removal of

zirconium would prevent a core melting,

it would provide more time.

Coming out of Fukushima, a number

of organizations around the world started

thinking about a zirconium-free core,

including ceramic fuel and stainless steel

fuel. EPRI’s concept is a molybdenum

fuel cladding coated with a thin layer of

zirconium.

32

NuclearPlantJournal.com Nuclear Plant Journal, September-October 2014