Optimum

Power

Coastdown

Strategy

By James Tusar, ExelonGenaration.

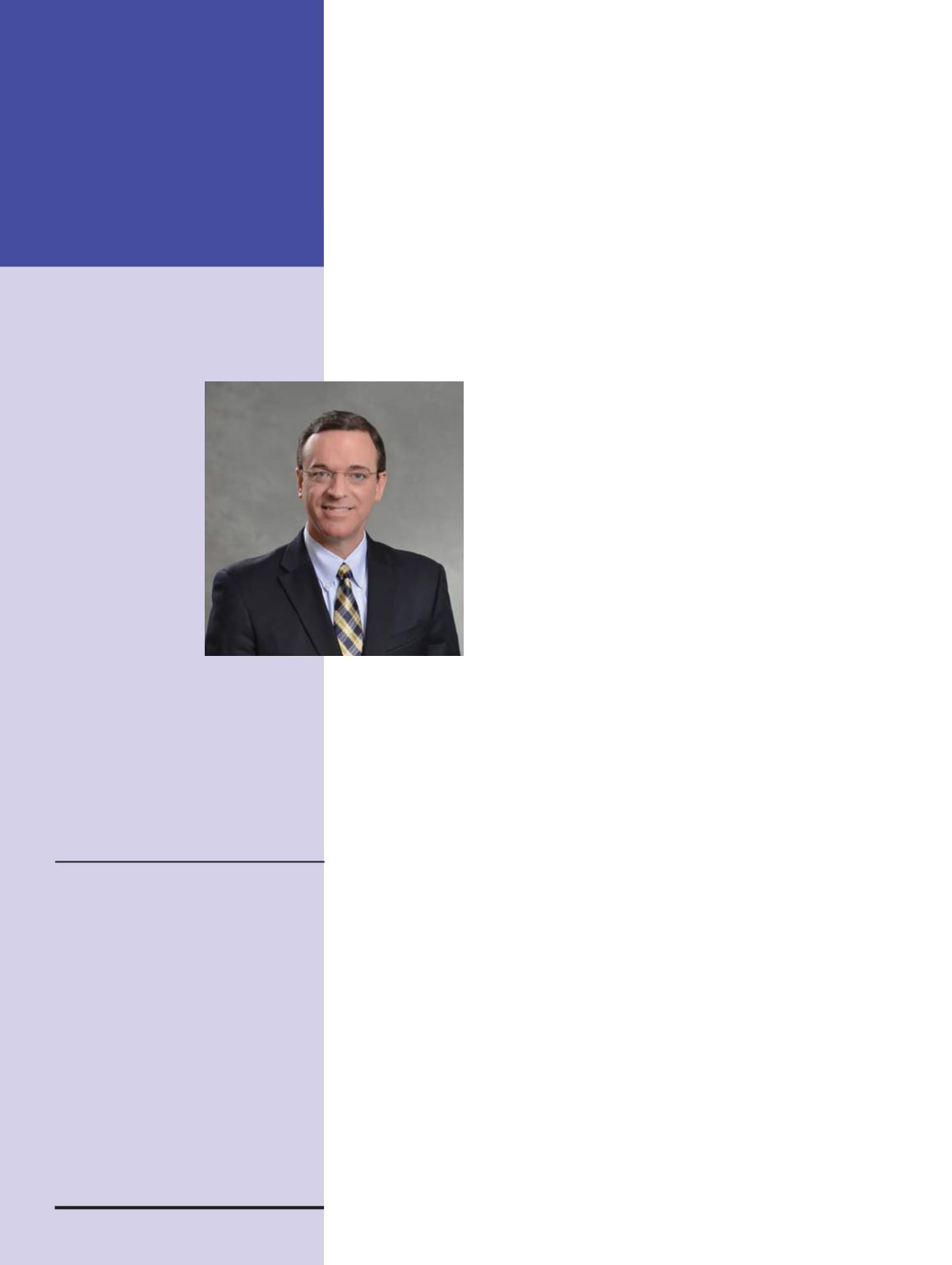

James Tusar

James Tusar is a graduate of

Pennsylvania State University with a BS

in Nuclear Engineering, from Drexel

University with an MS in Environmental

Engineering, and

has a Professional

Engineer’s License in

Nuclear Engineering.

He is currently

Senior Manager

of Boiling Water

Reactor Design for

Exelon Generation

which includes

responsibility for

nuclear fuel design,

reactor core design,

core management,

core monitoring

systems, and reload coordination for 8

reactors in 4 states.

James has been recognized for his

nuclear industry accomplishments with

ten (10) Nuclear Energy Institute (NEI)

Top Industry Practice (TIP) Awards.

Nuclear Energy Institute’s Top Industry

Practice (TIP) Awards highlight the

nuclear industry’s most innovative

techniques and ideas.

This innovation won the 2015 Nuclear

Fuel Award.

The team members who participated

included: James Tusar, Senior Manager,

Nuclear Fuels, Exelon; Dale Bradish,

Engineer, Nuclear Fuels, Exelon;

Richard McCord, Principal Engineer,

Global Nuclear Fuel; Adam Donell,

Reactor Engineer, Peach Bottom Atomic

Power Station, Exelon; Rob Lee, Nuclear

Fuel Buyer, Nuclear Fuels, Exelon.

Summary

Exelon’s optimum power coast-

down strategy is a top industry practice

in the Fuels category because it directly

addresses one of the key issues in the

nuclear power industry today – challeng-

ing economic conditions. The economic

challenge is primarily low electricity

prices, largely driven by the natural-gas

fracking boom and also the new renew-

able energy projects such as wind power.

Plants at four U.S. nuclear power stations

have recently shut down: San Onofre,

Kewaunee, Crystal River and Vermont

Yankee. Those closures have largely

been the result of falling power prices and

rising costs (main-

tenance,

repairs).

The optimum power

coastdown strategy

addresses the eco-

nomic challenges by

realizing significant

net cost savings for

every fuel cycle.

Power coastdown

is the planned reactor

operating condition at

the end of a fuel cycle

where

maximum

thermal power can no

longer be maintained due to fissionable

isotope depletion. This results in a

gradual decrease in core thermal power

(Graphic 1 on page 58). The optimum

power coastdown strategy uses an

automated method to determine the

optimum coastdown length (measured

in days) and maximum net cost savings

based on many economic and plant-

specific factors. Optimum coastdown

is ultimately achieved by balancing

the incremental fuel cost associated

with maintaining full power against

the generation cost associated with lost

generation during the coastdown.

On the surface, the optimum

power coastdown strategy may seem

counterintuitive. If a power plant is not

operating to maximum capacity at all

times, it is clear that maximum revenue

is not being generated. However, by

utilizing power coastdown, additional

energy is being produced after the reactor

has lost its ability to maintain full power.

This strategy essentially extends the cycle

length and produces additional power

(albeit at a de-rated condition) without the

necessity to purchase additional fuel. By

planning coastdown into the fuel cycle,

generation losses are offset by fewer new

fuel assemblies (or a lower enrichment)

which need to be purchased, resulting

in significant cost savings. Graphic 2 on

page 59 shows the net fuel cycle savings

as a function of planned coastdown

lengths. In this example, the maximum

net fuel cycle savings is $1.6 million

for a 24 day coastdown. On an Exelon

fleet basis, this conservatively results in

savings of at least $8 million annually.

This strategy maximizes the earnings and

cash flow from our assets.

Exelon’s optimum power coastdown

strategy is sophisticated, accounting

for the time cost of money (new fuel is

purchased two years in advance of the

power coastdown for a two year fuel cycle)

and multi-cycle energy carryover impacts

on future cycles due to the reload fuel

batch size reduction. The Exelon strategy

of optimum coastdown is embodied in

a software quality-assured spreadsheet

model, accounting for many plant and

cycle specific factors including the cost

of new fuel, replacement power costs

during the coastdown period, coastdown

rate, fuel cycle length, power level,

interest rates, and the energy capability of

the new fuel. The coastdown strategy is

applicable to both BWR and PWR units,

at all power levels and cycle lengths.

Safety Response

The optimum power coastdown

strategy enhances nuclear safety. This

strategy results in a decrease in the

number of reload fuel assemblies that

need to be purchased and loaded into the

core. On average, a 5% reduction in the

number of new fuel assemblies required is

realized. Therefore, fewer fuel moves are

necessary during a refueling outage and

generally less handling of fuel assemblies

is necessary (receipt, inspection and

storage). Nuclear safety is enhanced due

to a reduction in handling of new nuclear

fuel assemblies which reduces the risk of

accidents and human performance errors.

Also, full core discharge capability to

the spent fuel pool is being challenged

at some of our stations. The optimum

power coastdown strategy reduces the

total number of fuel assemblies purchased

56

NuclearPlantJournal.com Nuclear Plant Journal, July-August 2015