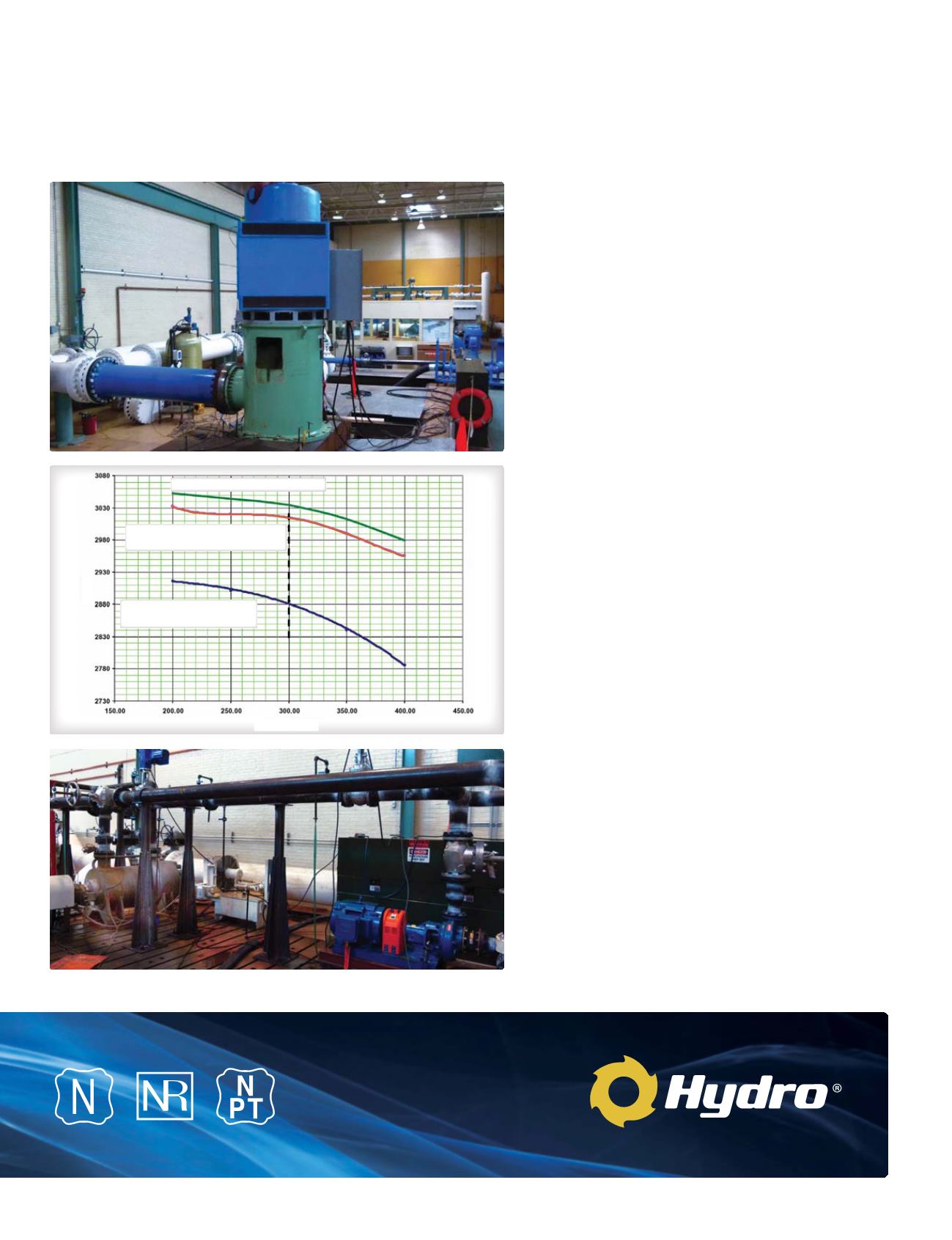

Endurance Testing for Service Water Pump

A 48-hour endurance test was performed for a

nuclear power plant when they contacted HydroAire

about conducting a research study. The power plant

engineers wanted to collect data to assess how

long the 1750 HP motor driving their essential

service water pump could continue to operate with

a deteriorating lower bearing. To learn the complete

details of this research study, contact Faisal Salman

a

t

or call

312-399-9913

.

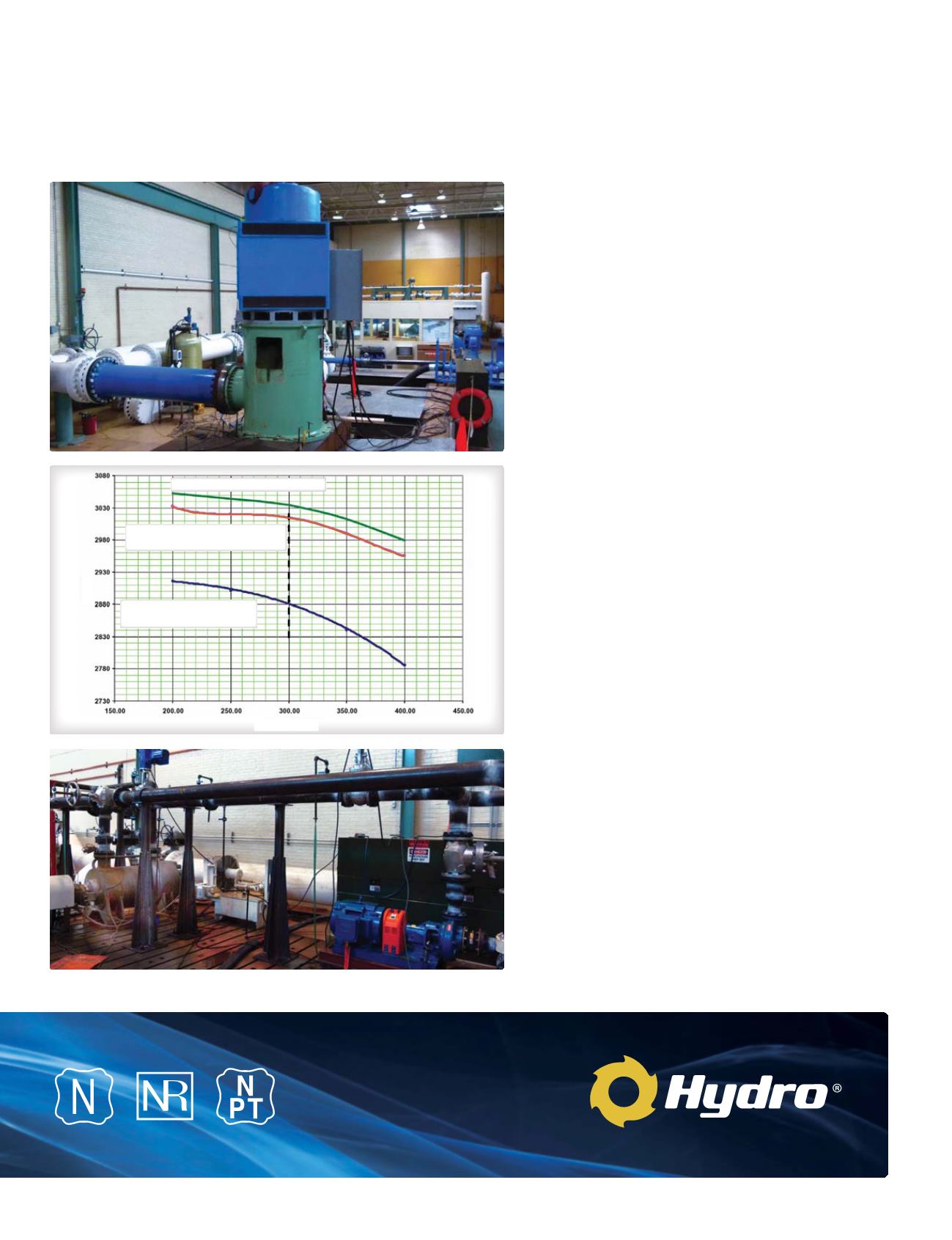

Performance Testing for Safety Injection Pump

Within a critical 2-week timeframe, HydroAire

helped a nuclear power plant avoid de-rating by

reverse engineering and rebuilding a Goulds

8-stagesafety injection pump rotor. The rotor, rebuilt

with engineered upgrades, was performance tested.

Performance was proven at 1288lbs. pressure –

8lbs. better than the original rotor and 88lbs. above

the minimum allowance. Read the full case study

at

Air Void Testing for Safety-Related Feed Pump

Hydro's engineers performed 40 air void tests in

10 days for a nuclear power company that had to

prove their Pacific 4” BFIDS auxiliary feed pump

would perform its safety-related service if an air

void greater than 2% passed through the pump.

Hydro’s Test Lab provided a live video feed of

real-time performance data for the NRC to monitor.

Read the full case study at

.

Proven Experience

Makes All The Difference

Actual Performance of Underfiled Impeller

Projected Performance of Impeller with

underfiling using Hydro's in-house program

Impeller without Underfiling

(spare rotor)

Characteristic curves

H (ft)

Flow (GPM)