50

NuclearPlantJournal.com Nuclear Plant Journal, May-June 2014

Multiple Defense...

while the safe shutdown earthquake

(SSE) adopted in the design is 0.3g,

which leaves a big safety margin.

Safety features:

The AP1000 nuclear power plant,

designed by Westinghouse, is a two-loop

pressurized water reactor (PWR) that

uses a simplified, innovative and effective

approach to safety. With a gross power

rating of 3,415 megawatt thermal (MWt)

and a nominal net electrical output of

1,250 MWe), the AP1000 reactor, with a

157-fuel-assembly core, is ideal for new

baseload generation.

The AP1000 PWR is based on a

simple concept: in the event of a design-

basis accident, such as a main coolant-

pipe break, the plant is designed to achieve

and maintain safe shutdown condition

without operator action, and without the

need for AC power or pumps. Rather than

relying on active components, such as

diesel generators and pumps, the AP1000

plant relies on natural forces - gravity,

natural circulation and compressed gases

- to keep the core and the containment

from overheating.

The AP1000 PWR provides multiple

levels of defense for accident mitigation

(defense-in-depth),

resulting

in

extremely low core-damage probabilities

while minimizing the occurrences of

containment flooding, pressurization and

heat-up. Defense-in-depth is integral to

theAP1000 plant design, with a multitude

of individual plant features including the

selection of appropriate materials; quality

assurance during design and construction;

well-trained operators; and an advanced

control system and plant design that

provide substantial margins for plant

operation before approaching safety

limits. The AP1000 PWR is also the only

Generation III+ reactor to receive Design

Certification from the U.S. Nuclear

Regulatory Commission (NRC).

Based on nearly 20 years of research

and development, the AP1000 plant

builds and improves upon the established

technology of major components used in

current Westinghouse-designed plants.

Components such as steam generators,

digital instrumentation and controls,

fuel, pressurizers and reactor vessels are

currently in use around the world and

have years of proven, reliable operating

experience.

Environment protection

After the completion of Sanmen

Phase I NPP, compared with ultra-

supercritical coal-fired units of the same

capability, the two units may help reduce

transportation of five million tons of high-

quality coal, emission of 11,490 tons of

sulfur dioxide, 19,088 tons of nitrogen

oxide and 1,345 tons of smoke and dust.

Contact: Jackie Smith, Westinghouse

Electric Company, 1000 Westinghouse

Dr., Cranberry Township, Pennsylvania

15632; telephone: (412) 374-3372,

email:

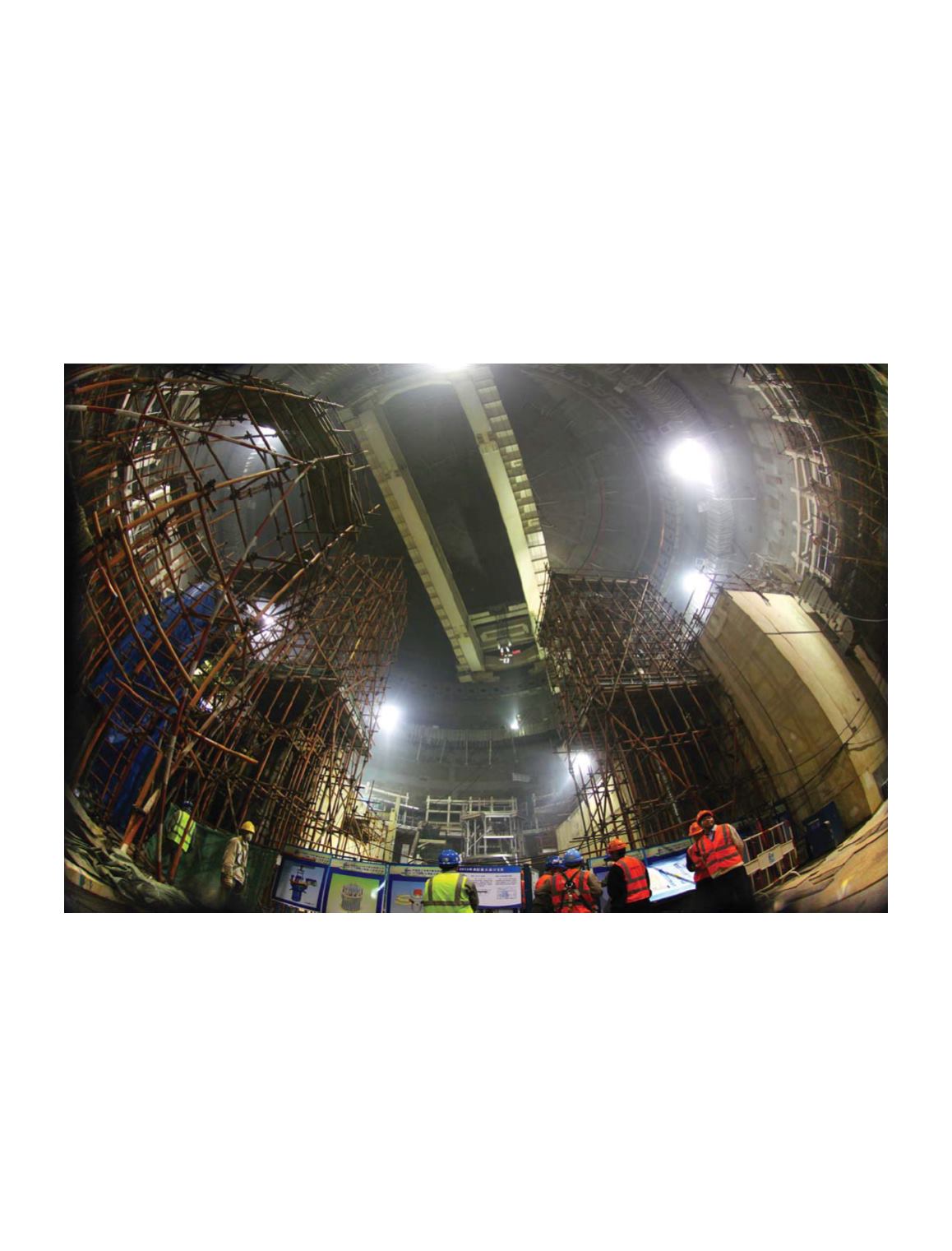

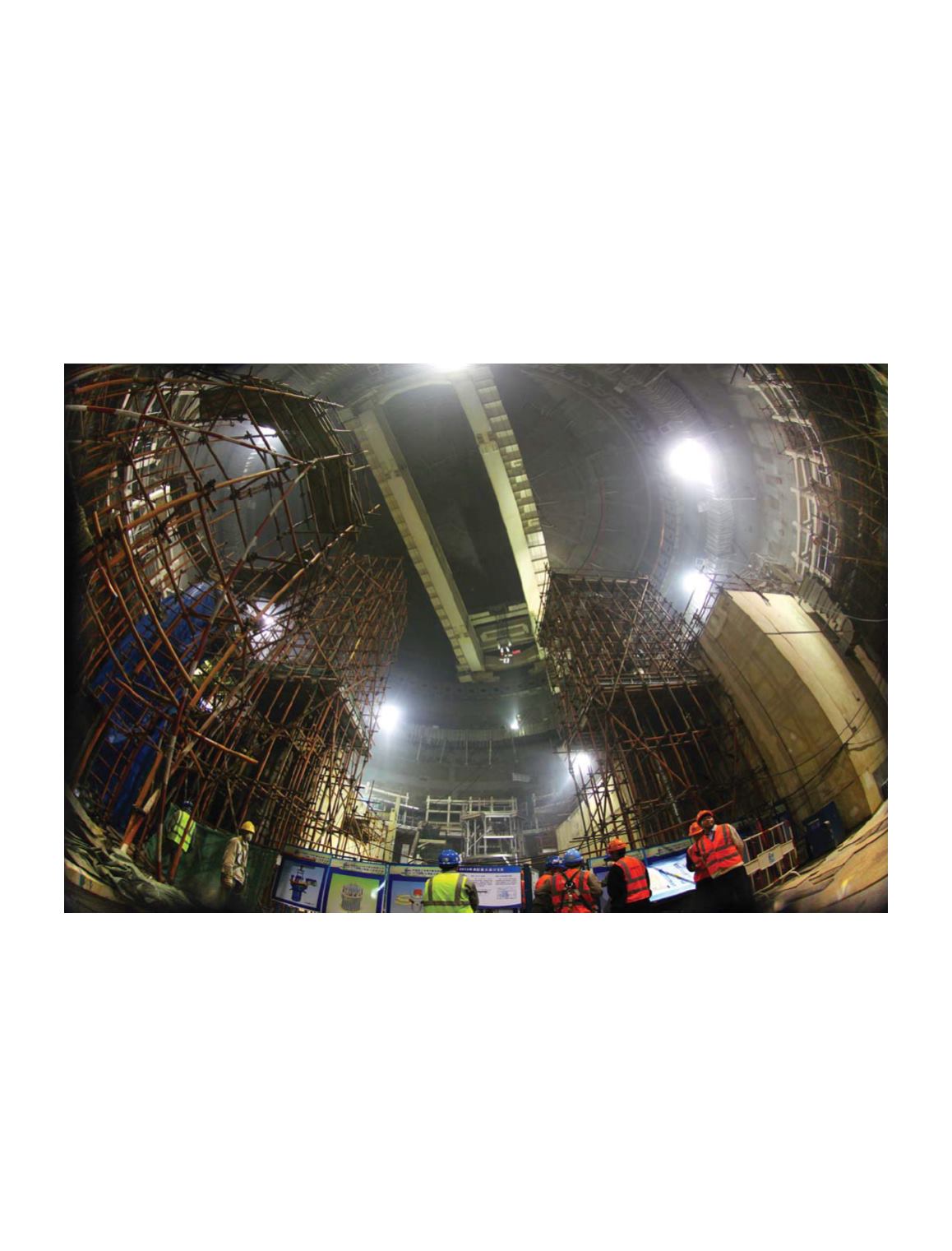

Internal view of Sanmen Unit 1 as of the end of March 2014. Photo courtesy of the Sanmen Nuclear Power Project.