Listening

to the

Voice of the

Customer

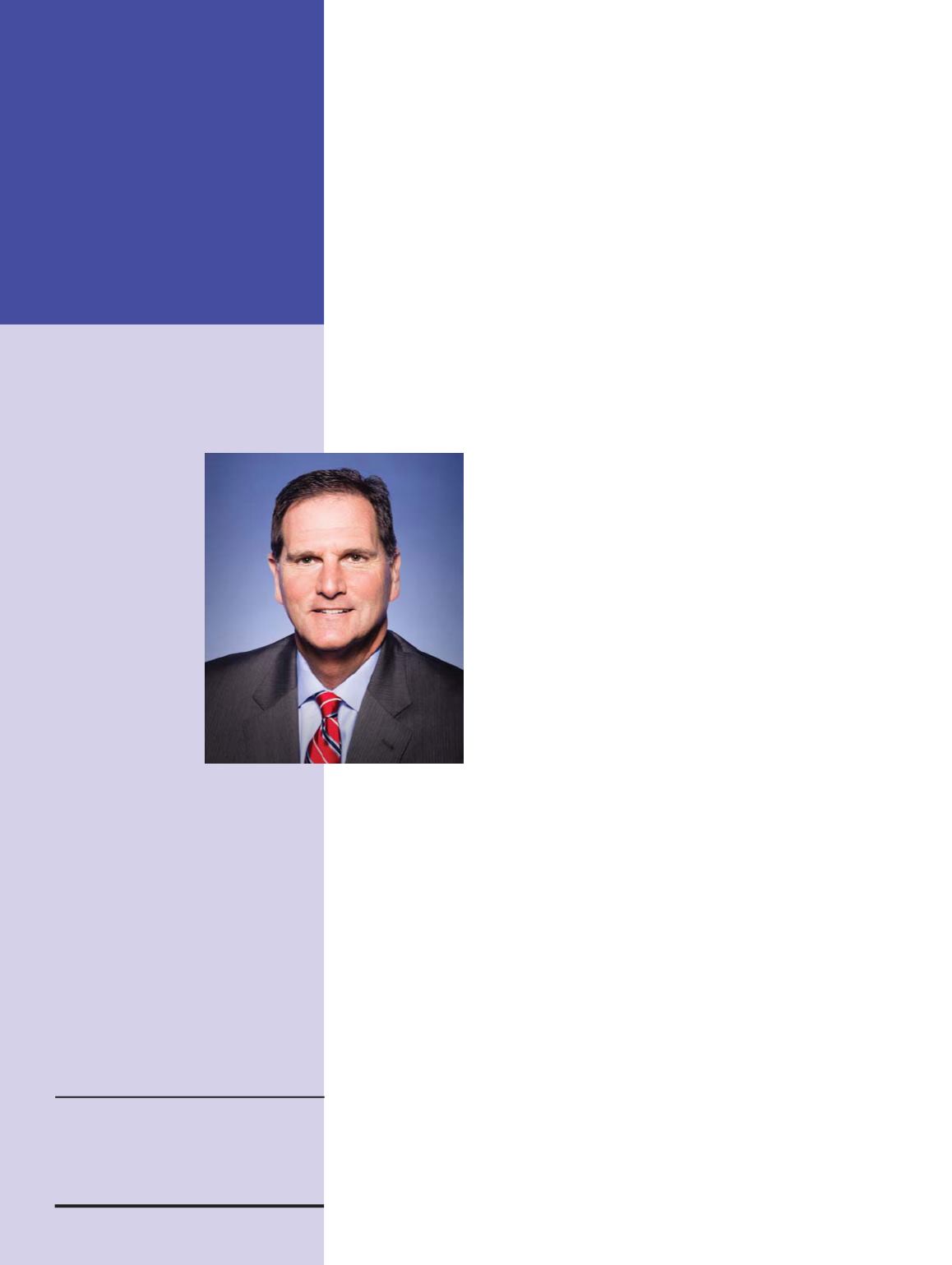

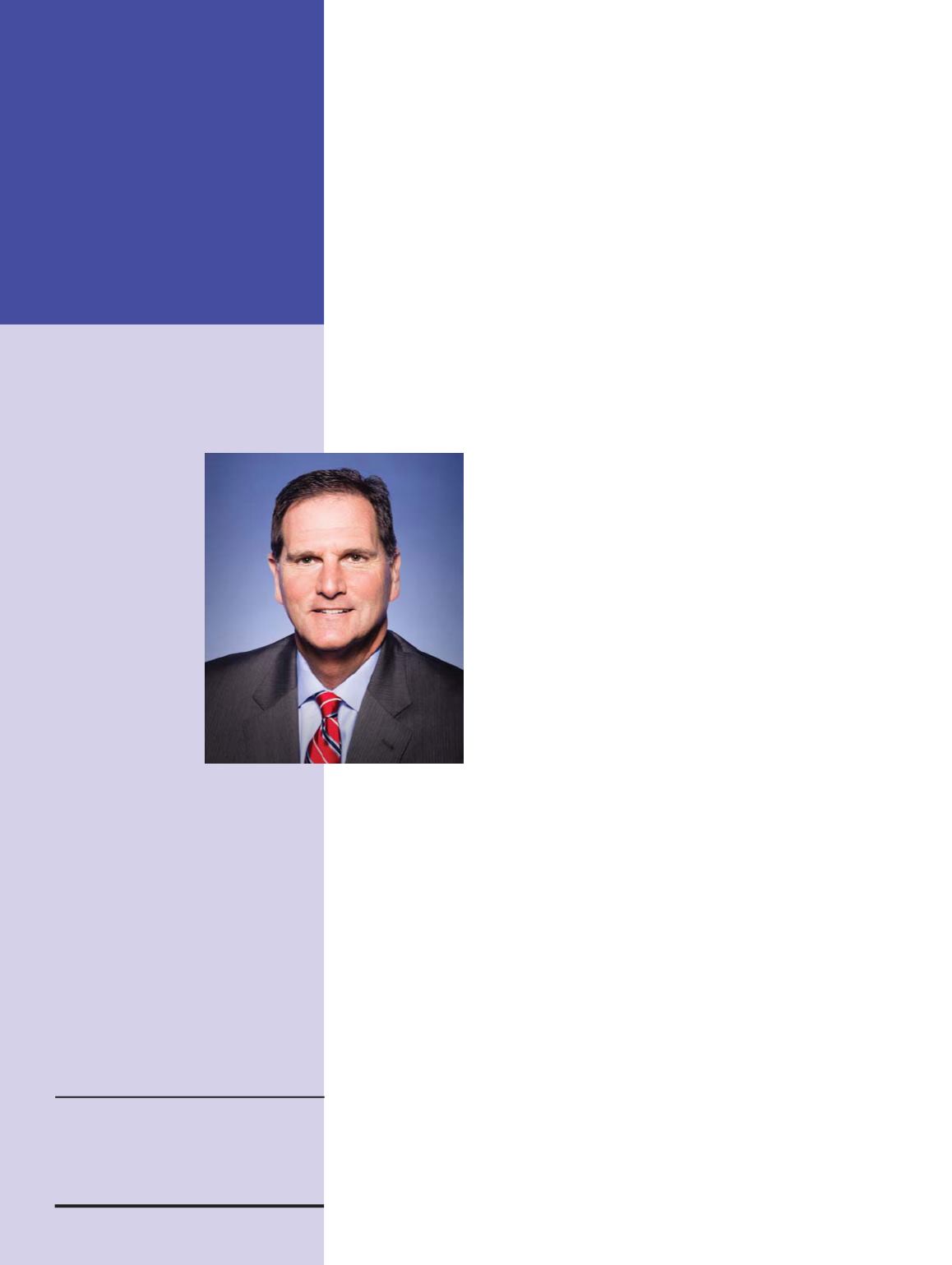

By Mark Marano, Americas Region,

Westinghouse Electric Company.

Mark Marano

Mark Marano brings more than 25

years of nuclear industry and vendor

operations experience as president,

Americas Region.

Marano is

responsible

for customer

relationships,

business plan

development, and

government and

regulatory affairs.

He oversees global

marketing initiatives,

commercial

operations,

and corporate

development,

strategy and facilities

management.

Prior to Westinghouse, he was senior

vice president of Business Development,

AREVA NP in Charlotte, North Carolina

(USA).

Marano holds board directorships

with Westinghouse Electric Company,

Toshiba America Energy Systems,

E4 Carolinas and National Association

of Manufacturers.

Marano graduated from Oswego State

University in 1984 with a Bachelor’s

degree in business administration.

An interview by Newal Agnihotri, Editor

of Nuclear Plant Journal, at Nuclear

Energy Institute’s Nuclear Energy

Assembly in Washington, D.C. on May

13, 2015.

1.

What’s the status of the digital

upgrade?

I see the current state of digital

upgrades in the North American

marketplace through both the utility and

vendor lenses, having spent almost 20

years of my career at five utilities, and

understand reasonably well the utility

business model and how utility customers

pursue the project justification process. I

am hopeful that this knowledge serves

both Westinghouse and our customers. I

think Instrumentation and Control (I&C)

upgrades present a challenging business

case for some utilities – while it’s a

significant upgrade, it also is a substantial

investment. Moving from a manual

to an automated digital environment

is paradigm changing and touches

everything from a plant’s instrumentation

signals to information

received about the

reactor. There is also

uncertainty

around

the timing of license

approval from the

Nuclear Regulatory

Commission.

In the last few

years,

the

U.S.

nuclear

energy

industry has seen a

decline in investments

such as I&C upgrades

primarily because an

increasing amount of

capital resources are

consumed by regulator-required work

that is needed to meet post-Fukushima

regulations.

Additionally, power prices in the

U.S. have decreased significantly,

due primarily to low gas prices and

subsidized renewables. This has reduced

the availability of capital for long-term

investments and has resulted in utilities

shifting to performing digital upgrades in

steps. The utilities understand that analog

may not be the long-term ideal situation.

Eventually, if plant life is to extend to 60

or 80 years, a plan must be in place to

address I&C system replacements. But in

the interim, in order to manage budgets,

utility customers know that Westinghouse

can provide new component replacements

for their plants’ systems until such time as

a complete upgrade is required.

Once our customers have settled

on expenditures related to security and

post-Fukushima

modifications,

the

Ovation

®

system is the Westinghouse

system of choice for full I&C upgrades.

We stand ready to provide full I&C

upgrades when our customers are ready.

Currently, we are doing some smaller-

scale I&C installations and component

replacements.

2.

What are the major challenges with

analog right now?

The main challenge for analog

systems is maintaining them. Will the

replacement parts be there when they are

needed? We know of some component

replacement vendors that have had some

challenges in both quality and availability.

Some are either no longer in business or

have been acquired by another company.

So the big questions for utilities are: will

the needed components be available, and

will the components function as required?

At Westinghouse, we deploy more

than 100,000 genuine nuclear replacement

parts and components annually to the

global nuclear fleet. This is one way

we help utilities meet the challenge of

maintaining the safety and efficiency of

their analog systems until they are ready

to gain the added benefits of digital.

Westinghouse replacement parts

and components are cost-effective, high-

quality, nuclear grade and are available

for a wide variety of reactor designs.

Westinghouse maintains a robust quality

assurance program and equipment

qualification program for its replacement

parts

and

components

business.

Westinghouse has strong partnerships

and formal technical agreements in place

with original equipment manufacturers

that allow us to access proprietary

manufacturing and design information as

needed.

3.

Are there a lot of utilities still going

ahead with digital upgrades?

Many utilities seem to be performing

digital upgrades in steps. We are currently

performing more of what we call drop-

in solutions. These are digital upgrades

focused on specific existing systems

versus digital upgrades of a complete I&C

system. We do this by applying pragmatic

long-term asset management methods

40

NuclearPlantJournal.com Nuclear Plant Journal, July-August 2015